Products丨The application of IMERYS conductive graphite in lithium batteries

Release time:

2025-05-16

In addition to transmitting electrons and reducing polarization during the charging and discharging of lithium-ion batteries, conductive agents will also have a certain impact on the flexibility, compaction density, adhesion and other properties of the electrode sheet during the lithium battery manufacturing process. Currently, the conductive agents commonly used in the market are mainly conductive carbon black, conductive graphite, single-wall, multi-wall carbon nanotubes, carbon fibers, and graphene.

Product Introduction

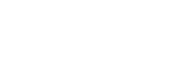

In IMERYS's products, KS6L/SFG6L/KS15L/SFG15L is a graphite conductive agent. This type of conductive graphite is widely used in lithium batteries. The following are the basic parameter information of conductive graphite:

IMERYS conductive graphite product series

(I) Application of IMERYS conductive graphite in lithium batteries

IMERYS conductive graphite is added to the positive electrode formula to provide the conductivity and slippage between the main material particles, thereby improving the compaction density and flexibility of the electrode sheet, reducing particle crack defects, and improving long-term electrical performance.

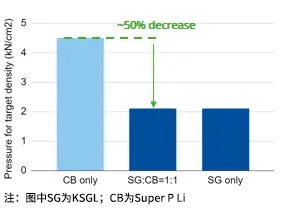

When rolling the polarizer to the target compaction density, adding IMERYS conductive graphite can significantly reduce the required pressure (by~50%), thereby significantly reducing the cracking and surface defects of active materials caused by high pressure, reducing side reactions, and improving high-temperature storage performance and cycle life.

(II) Application of IMERYS conductive graphite in negative electrode

IMERYS conductive graphite is added to the negative electrode formula, which can be used as the main material of the negative electrode (Li ions can be deintercalated, with a capacity of ~350mAh/g), negative electrode conductive agent, and negative electrode heat dissipation agent. At the same time, it can suppress the floating of the Binder electrode sheet in the coating process and improve the adhesive force of the electrode sheet.

1) Use 4% conductive graphite KS6L in the negative electrode formula, and the cell resistance is reduced by ~10%;

2) After adding IMERYS artificial graphite, the thermal conductivity of the negative electrode material layer can be improved, thereby improving the battery temperature rise;

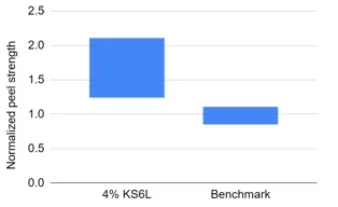

3) After adding IMERYS artificial graphite, the peeling force of the negative electrode sheet can be increased (suppressed the Binder floating during the coating and drying stage).

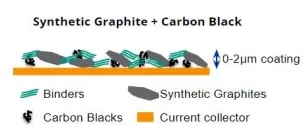

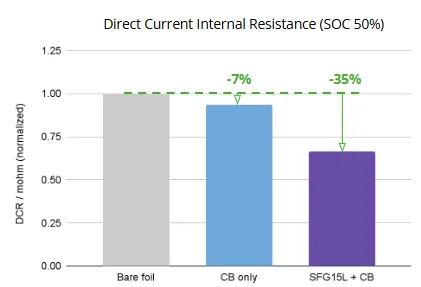

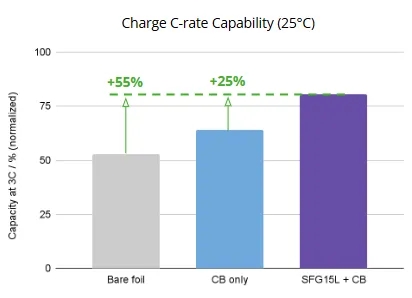

(III) Application of IMERYS conductive graphite on carbon coating

IMERYS conductive graphite is added to the charcoal coating formula to improve the adhesion of electrode sheets, significantly reduce battery resistance, and increase charge discharge rate.

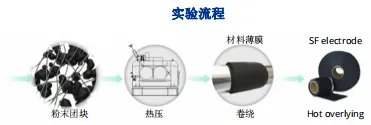

Application of IMERYS conductive graphite in dry-method electrode sheet technology

IMERYS conductive graphite KS6L is added to the dry-form electrode sheet process. The conductive graphite is used as the lubricant in mechanical processing and is easier to disperse the main material and binder. The dry- form extrusion process window is larger, and the electrode sheet resistance and the electrode sheet tensile strength are improved.

Summarize

The IMERYS conductive graphite KS/SFG series belongs to the scale-layered artificial graphite. By adding a small amount of conductive graphite to the positive and negative electrode formula, positive and negative electrode primer and dry electrode sheet formula of lithium battery, different special functions can be exerted.

01

In the positive electrode formula, conductive graphite can reduce rolling pressure, increase electrode compaction density, improve electrode flexibility, and significantly avoid cracking/crushing on the surface of the main material particles during the rolling process, thereby affecting long-term electrical performance.

02

In the negative electrode formula, conductive graphite can be used as the main material of the negative electrode and also as a conductive agent, which can significantly improve the electrode resistance and internal heat transfer of the battery cell. At the same time, the layered structure of conductive graphite can reduce the floating of SBR in the electrode during coating and drying, thereby improving the adhesion of the electrode.

03

In the formulation of carbon-coated aluminum foil and carbon-coated copper foil, appropriate addition of conductive graphite can improve coating consistency, reduce coating resistance, and improve adhesion.

04

In the dry-form electrode sheet formulation, conductive graphite makes the dry-forming extrusion process easier (improving inter-grain lubrication), while improving the dry-form electrode sheet resistance and tensile strength of the electrode sheet.