Products丨 Recommended application of Wu Yu Chemical PVDF in lithium batteries

Release time:

2025-04-03

introduction

Polyvinylidene Fluoride (PVDF) is a polymer material with excellent performance, with excellent chemical stability, thermal stability, mechanical strength and electrical insulation. These characteristics make PVDF widely used in many fields. This article focuses on the application of PVDF in lithium-ion batteries.

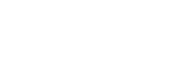

Introduction to the application services of PVDF in lithium-ion batteries

PVDF is mainly used as a binder in lithium-ion batteries, and is used to adhere electrode active materials (such as lithium cobalt oxide of the positive electrode and graphite of the negative electrode) to the current collector (such as copper foil, aluminum foil).

KUREHA's PVDF

In 1970, Wu Yu Chemical took the lead in the industrial production of polyvinylidene fluoride resin (PVDF) in Japan, with the product name KF Polymer. Since it was adopted as the world's first commercial lithium-ion battery (LiB) in 1991, KF Polymer has numerous use cases. Wu Yu Chemical has continuously accumulated application experience in the battery field and has developed different models of PVDFs according to different needs.

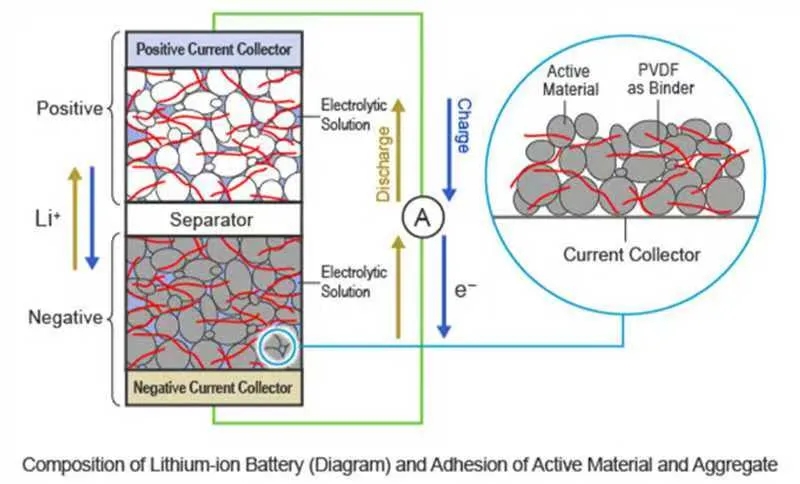

【Hori-aggregation product (HOMO)】

It is made of VDF polymerization and can select different molecular weight grades according to your needs.

【Copoly.)】

By copolymerizing VDF with other monomers, its performance can be improved, such as improving flexibility, improving alkali resistance and viscosity enhancement of the slurry.

【Modified】

The adhesive strength of PVDF is improved by adding functional groups.

【Wu Yu Chemical Product Model】

【Three-way system PVDFW#9700 and three-way high-nickel system antigel product W#7500】

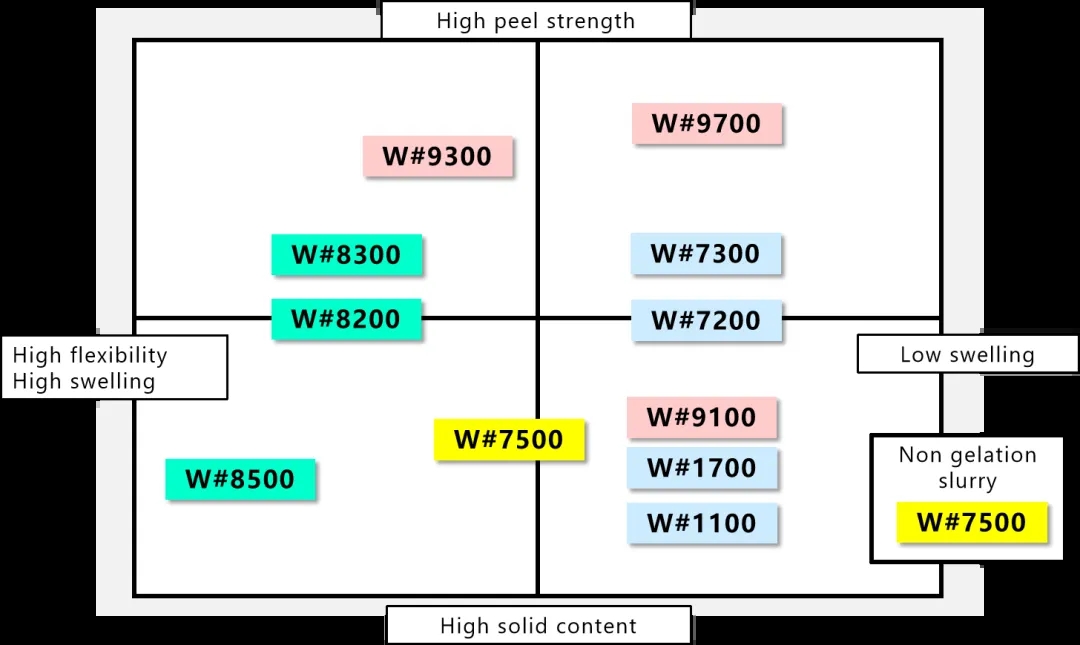

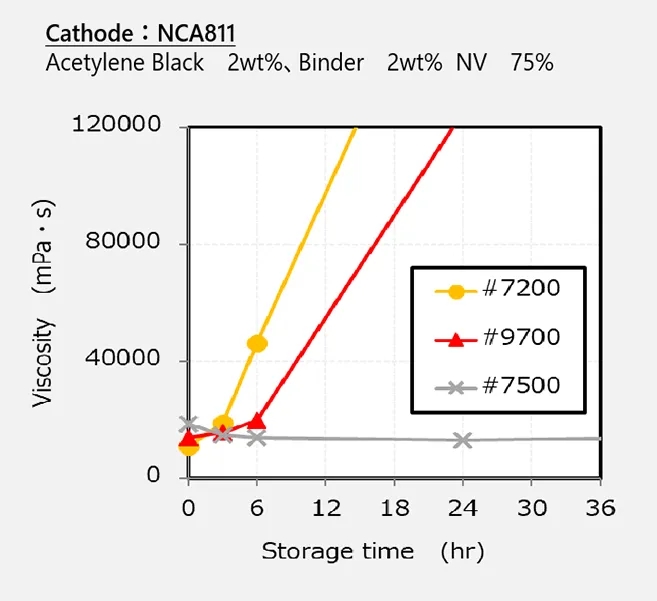

In ternary high nickel systems, the slurry gel phenomenon is often caused by the alkali production of the active substance itself, and W#7500 was developed to solve this problem. As shown in the figure, a slurry is made using ternary high nickel 811. Compare W#7500, a homopolymer W#7200 with the same molecular weight as W#7500, and W#9700 that is actually mass-produced in ternary units. After W#7500 is stored for 36 hours, the slurry viscosity can remain unchanged, while W#7200 has shown a significant viscosity increase in 6 hours. W#9700 is between W#7500 and W#7200. From this we can see that W#7500 has excellent anti-gel properties and is currently used in ternary systems.

summary

In ternary high nickel systems, the slurry gel phenomenon is often caused by the alkali production of the active substance itself, and W#7500 was developed to solve this problem. As shown in the figure, a slurry is made using ternary high nickel 811. Compare W#7500, a homopolymer W#7200 with the same molecular weight as W#7500, and W#9700 that is actually mass-produced in ternary units. After W#7500 is stored for 36 hours, the slurry viscosity can remain unchanged, while W#7200 has shown a significant viscosity increase in 6 hours. W#9700 is between W#7500 and W#7200. From this we can see that W#7500 has excellent anti-gel properties and is currently used in ternary systems.

Service Hotline:

Focus on us

Contact Information

E-mail:hy@haiyi21cn.com

Address: East Block, 3rd Floor, Mid-term Building, 2000 Zhongshan North Road, Putuo District, Shanghai

Hotline:

400-088-7155

-

E-mail:hy@haiyi21cn.com

Address: East Block, 3rd Floor, Mid-term Building, 2000 Zhongshan North Road, Putuo District, Shanghai

All rights reserved©2022 Shanghai Haiyi Technology & Trade Co., Ltd

The license number for the production and operation of hazardous chemicals is: Shanghai (Feng) Emergency Management Xu [2021]202233(FY)