Product丨Added color slurry for PVC-based anti-stone impact coatings

Release time:

2025-10-17

PART 01

What is anti-stone chip coating?

Anti-stone coating, as the name suggests, is a special coating specially designed to resist the impact of flying rocks, gravel and other hard objects. It is usually not a single topcoat, but a base or middle layer of paint with high elasticity, high toughness and good adhesion.

In cars, it is mainly applied to the parts of the vehicle that are most vulnerable to stone impact, such as:

Chassis (especially hubcaps, lower side members, floor panels)

Wheel arch inner panel

door sill

lower part of bumper

Lower body area

Its main function is to provide a "soft armor" for the substrate (usually metal or plastic), absorbing and dispersing impact energy through its own deformation, thereby preventing the substrate from being punctured and corroded, and ensuring the integrity of the topcoat.

PART 02

The main features of PVC (polyvinyl chloride)-based anti-stone coating

Features: Currently the most widely used in the automotive industry. It is a kind of plastisol that requires high-temperature baking (about 140°C) to plasticize and form.

advantage:

Excellent toughness: good elasticity, can effectively absorb impact energy.

Strong adhesion: firmly combined with electrophoresis primer.

Resistant to corrosion and chemicals: excellent performance.

Different thicknesses can be sprayed: from hundreds of microns to several millimeters to meet the needs of different protection levels.

Disadvantages: Contains chlorine, which puts great pressure on environmental protection; baking energy consumption is high.

Application: Standard equipment on most modern passenger cars.

PART 03

Colors of PVC (polyvinyl chloride) based stone chip resistant coatings

Stone chip paint itself is colored, but the final color we see is usually determined by the topcoat over it.

(1) Color in original automobile manufacturing

In the automotive production line, anti-stone coatings appear as an intermediate layer, applied between the electrophoretic primer and topcoat.

Most common colors: gray, light gray or gray-black.

Conclusion: When you lift the car chassis and see the gray, thick and elastic coating, it is the most common original factory anti-stone coating.

(2) Color in the aftermarket (such as "chassis armor")

For the convenience of marketing and construction, products in the aftermarket have more diverse color choices.

1. Black: This is the most mainstream and popular color. reason:

Beautiful and unified: The car chassis itself is mostly dark, and the black coating looks neat, hidden, and unobtrusive.

Dirty resistance: The chassis is easily stained with dirt, and black is the best way to "hide dirt and dirt."

Psychological feeling: It feels more solid and professional.

2. Gray, gray and black: imitating the original factory style, which is also relatively common.

3. Other colors (such as white, red, etc.), these colors are usually used for special purposes:

Display product thickness: The white coating can very clearly demonstrate the uniformity and thickness of spraying, and is often used for product demonstrations or high-end construction shops to show their workmanship.

Brand Identity: Some brands may use specific colors as their product identification.

Disadvantages: Very not resistant to dirt, and if the spraying process is not good, it will be very obvious. Therefore, there are few choices for daily family cars.

PART 04

Why use color paste and the advantages of adding color paste

- Clean production, environmental protection.

- Adequate grinding and good batch stability.

- Multiple screening of raw materials and strict material selection ensure stable quality.

- The product is positioned as high-end, does not contain chlorinated paraffin, complies with ROHS standards, and is the preferred color paste for export orders.

PART 05

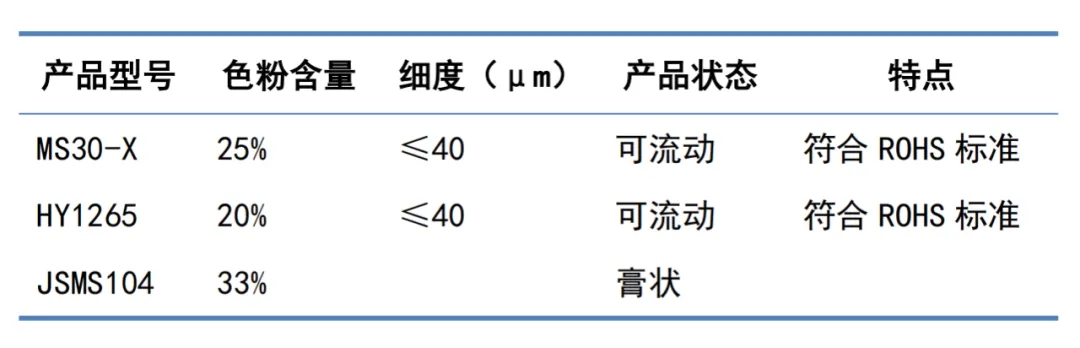

Features of main product models of PVC-based anti-stone impact coatings