Product丨OCSiAl high solid content single-walled carbon nanotube new product launch|Improve the efficiency of lithium-ion batteries

Release time:

2023-10-13

Through technological innovation, OCSiAl has increased the production capacity of single-walled carbon nanotube powder and launched a new generation of high-solid content conductive products. Compared with existing products, the solid content has been increased by more than 2 times, further reducing the cost of using single-walled carbon nanotubes and improving cost-effectiveness.

The new generation of high-solid conductive products is already available in the Chinese market and will be promoted to the European market in the next step.

OCSiAl is a global leader in single-walled carbon nanotube (SWCNT) technology and manufacturing. By expanding the capacity of single-walled carbon nanotube synthesis facilities and improving the cost-effectiveness of TUBALL BATT products, OCSiAl has further consolidated its leading position in the global market for single-walled carbon nanotubes. In addition, compared with existing solutions, the new generation of conductive agent slurry has a 2.5-fold increase in single-walled carbon tube content, which will help further reduce the cost of lithium-ion battery products and improve the economics of Chinese battery manufacturers using high-quality single-walled carbon nanotubes from Europe.

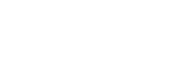

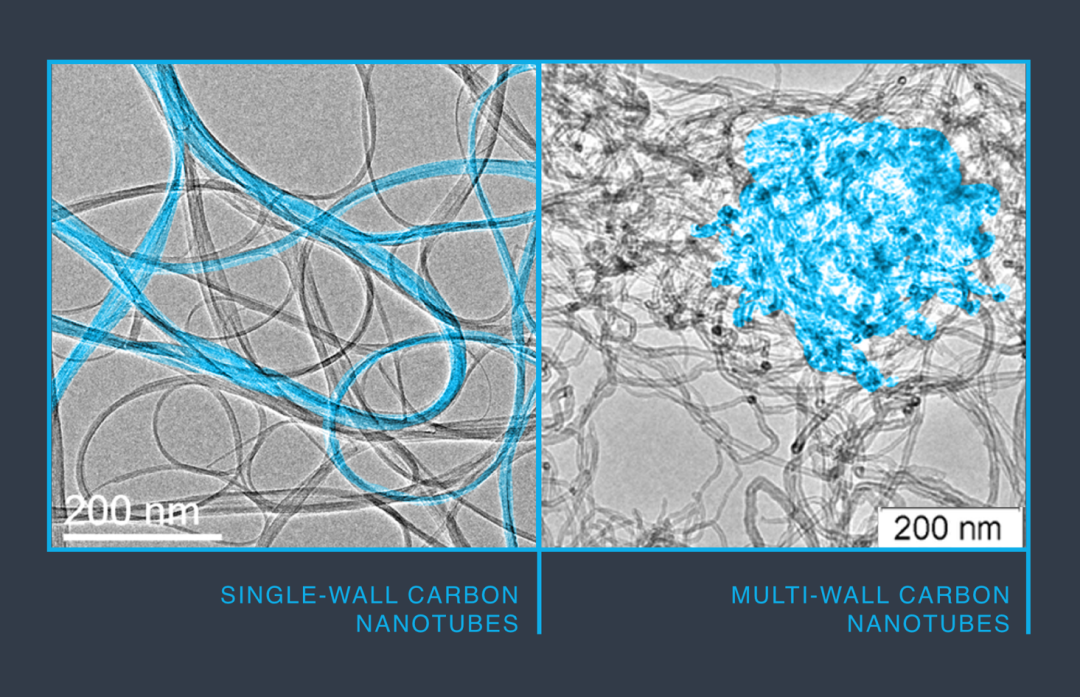

For both positive and negative electrode applications, OCSiAl provides high solid content solutions. Compared with traditional conductive agents, such as multi-walled carbon nanotubes, carbon black, etc., TUBALL BATT has a higher cost-effectiveness. Compared with multi-walled carbon nanotubes, single-walled carbon nanotubes only require 1/10 of the addition.

The new TUBALL BATT NMP product with 1% solid content is used for the positive electrode, and the TUBALL BATT H2O with 0.8% solid content is used for the negative electrode, which can effectively help lithium-ion battery manufacturers to further improve product performance. The core advantage of the new conductive liquid product comes from the high content of single-walled carbon nanotubes, which is 2-2.5 times higher than the current products. "The single-walled carbon nanotube solid content of the new product represents the industry-leading level among all series of single-walled carbon nanotube-based dispersions. Adding the same amount of single-walled carbon nanotubes to the battery pole piece now requires less solvent, so battery manufacturers can get a higher solid content in the slurry. In addition, compared with existing products, high-solid dispersions are undoubtedly more cost-effective and greatly improve cost performance.

In addition, during the dispersion manufacturing, transportation, storage and battery manufacturing process, due to the reduction in material consumption, the logistics cost is also reduced by 2-2.5 times, which is conducive to the sustainable development of the industry.

Both new products are currently produced locally in China.

OCSiAl produces high-quality single-walled carbon nanotubes under the TUBALL brand. Currently, TUBALL single-walled carbon nanotubes show superior performance to other single-walled carbon nanotubes on the Chinese market. TUBALL single-walled carbon nanotubes have a diameter of 1.6 (± 0.4) nm, a length of more than 5 μm, and an aspect ratio of more than 3000. OCSiAl provides high-quality single-walled carbon nanotubes for lithium-ion batteries with a single-walled carbon nanotube content of more than 99%. The G/D ratio is an important indicator for measuring the quality and degree of defects of single-walled carbon nanotubes, and based on this, TUBALL single-walled carbon nanotubes are high-quality products.

The single-walled carbon nanotubes produced by OCSiAl have unique morphological, physical and mechanical properties such as high aspect ratio and high flexibility, making them high-performance conductive and reinforcing materials. In contrast to short and hard multi-walled carbon nanotubes, single-walled carbon nanotubes establish a strong and long-range conductive network structure between the active material particles, improving the key properties of the battery, such as improved cycle life, reduced DCR, improved rate performance and cohesion between active materials. This is especially important for systems with high volume expansion, such as silicon-containing negative electrodes. OCSiAl's single-walled carbon nanotubes can greatly alleviate the degradation problem and effectively promote the industrial application of silicon as a high-capacity negative electrode active material. Today, thanks to TUBALL single-walled carbon nanotubes, silicon-oxygen negative electrodes can try 90% of silicon-containing materials, helping industrial batteries achieve an energy density of 360kwh/kg or even higher.

In the positive electrode, the tough TUBALL single-walled carbon nanotube network can improve the cohesion - strengthening the bonding between active material particles - and is currently widely used in thick coating systems. In future thick coating systems, it will help improve the flexibility and stability of ternary and iron-lithium thick electrodes.

OCSiAl is headquartered in Luxembourg and has been deeply involved in the Chinese lithium battery market for 8 years. In 2019, Shanghai Haiyi Technology and Trade Co., Ltd. (Haiyi), a leading Chinese chemical trader/manufacturer, launched local large-scale production of TUBALL BATT, a single-walled carbon nanotube dispersion for lithium-ion battery applications, to improve the resilience of the battery single-walled carbon nanotube solution supply chain to the Chinese market. At the same time, Shanghai Haiyi Technology and Trade Co., Ltd. is also committed to continuously expanding production capacity to meet the growing market demand.

Shanghai Haiyi Technology & Trade Co., Ltd. Single-walled carbon nanotube slurry factory

Location: Huzhou. Anji

System: IATF 16949

Capacity:

Single-wall water-based slurry 4000MT, second phase capacity 10000MT.

Single-wall solvent-based slurry 1000MT, Phase II capacity 5000MT.

It is expected that the production line expansion will be completed in 2023 and put into production in 2024.

Welcome all kinds of partners and friends to visit and guide us!