Products丨Application of Ashland cellulose ether in ink industry

Release time:

2023-11-10

Introduction to Ashland

Ashland is a global leading additives and specialty products company that actively practices the concept of sustainable development. Ashland is the leader in the global cellulose ether production market and has production bases in China, the Netherlands and the United States. It provides high-quality and reliable products for many personal and industrial consumer products, including coatings, personal care, oil and gas, construction, pharmaceuticals, printing inks, etc.

Cellulose ether

Cellulose ethers are water-soluble polymers made from cellulose, the main component of the primary cell walls of green plants and the most common natural polymer on earth.

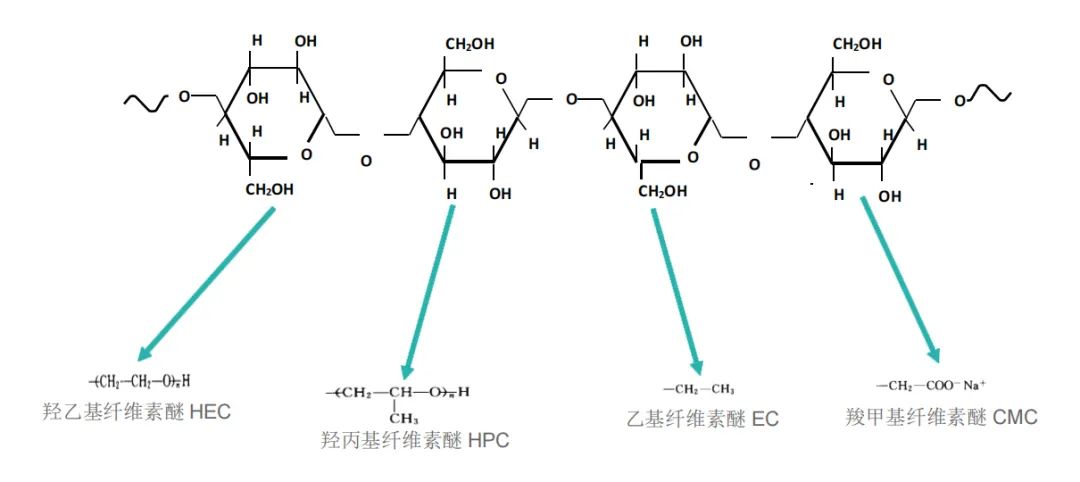

Cellulose ether classification:

1. Hydroxyethyl cellulose HEC: It is a non-ionic cellulose ether that can be dissolved in water to form a transparent viscous solution. Its solubility is not affected by pH value and it has good color development and compatibility.

2. Hydroxypropyl cellulose ether HPC: It is a non-ionic water-soluble cellulose ether. Unlike HEC, HPC is not only soluble in water, but also in polar organic solvents such as methanol, ethanol, and isopropanol. Low molecular weight specifications are mainly used as adhesives, and high molecular weight specifications are used to prepare hydrophilic gel skeleton sheets.

3. Ethyl cellulose ether EC: It is a non-ionic cellulose ether that is insoluble in water but soluble in organic solvents. Ethyl cellulose is mainly used as tablet adhesive and film coating material due to its water insolubility.

4. Carboxymethyl cellulose CMC: poor biological stability, poor water resistance, no hydration treatment, and difficult to dissolve.

Natrosol HEC Thickener

Natrosol HEC is a natural product and an excellent thickener with excellent biostability to prevent mold in solution. It provides good consistency in water-based inks, reduces splashing, has good color development and compatibility, and provides good dispersion and stability for various substances in inks. HEC can provide good pseudoplasticity in water-based inks and has a wide range of compatibility with pigments, emulsions, surfactants, emulsifiers and defoamers.

HEC thickening mechanism: high thickening efficiency is ensured through hydrogen bonding and main chain entanglement.

HEC has a range of products with different viscosity ranges

Application direction:

1. Water-based gravure ink

HEC has a high efficiency in thickening the water phase. The system can be used with a large amount of water without affecting the printing performance. It has excellent compatibility and is easy to add. It is mainly used in film substrates, decorative paper, etc. The main models are 250HBR, 250HHBR, and 250MHBR.

2. Water-based color paste

HEC has high thickening efficiency in water-based color paste, excellent compatibility, good dispersibility and stability, and is available in 250HBR, 250MHBR, 250HR and other models.

3. Water-based screen printing ink

Glass glaze, mainly used on solar white backplane glass, also known as glass ink, mainly uses hydroxypropyl cellulose, which has better solubility and stability.

Questions & Answers

Q: How to add hydroxyethyl cellulose during use?

A: It can be added during the grinding or high-speed dispersion and adjustment stages. Directly adding during the grinding or high-speed dispersion stage can appropriately increase the viscosity of the grinding base and improve the grinding efficiency. During the adjustment stage, it is recommended to add it in the form of an aqueous solution, and the aqueous solution is generally 2-3% in concentration. Generally, hydroxyethyl cellulose should be slowly added to water under constant stirring. After stirring for 3 to 5 minutes, add alkaline products such as pH regulators to facilitate the full dissolution of cellulose.

Q: What are the differences between the different types of hydroxyethyl cellulose? Which types are recommended?

A: The difference between different models is mainly in viscosity. 250HBR and 250HHBR are recommended. Since the molecular weight and viscosity are suitable for the largest dosage, 250HHBR has higher viscosity and molecular weight, and has better thickening effect.